Rapid Prototyping, Stereolithography, 3-D Printing of Lost-Wax models for your favorite hobby!

Hello, and welcome to Pacific Locomotive Works! We are the source for your custom model casting needs!

In brief, we take drawings, blueprints or sketches from you, and generate

a computerized model called a solid. This is accomplished utilizing

a 3-D modeling program such as AutoCAD, SolidWorks or Pro/E. Once the

model is programmed in the computer, we send you JPEG pictures to proof

the model. When you are satisfied, we produce the model in a form of

wax utilizing our SolidScape T-66 modeler. Once this is finished, the

model (which sometimes is made in pieces) is assembled and sent to one

of our brass foundries. The wax master is melted-out in a mold and a

brass master is made (lost-wax.). This master can then be polished,

machined, or fixed up any way you like. Finally, once the master is

to your liking, it is returned to the foundry where a rubber mold is

produced, waxes are pulled from the rubber mold, and production parts

are investment cast via lost-wax.

Gone are the days when a smith had to carve a block of paraffin with

a Dremel tool or produce small parts out of styrene to produce a master!

This new process allows all mistakes to take place on the computer,

allowing you to evaluate the model from any angle. It is then exported

to the 3-D modeler and your parts are produced. They can be made actual

size, or the 4% mold shrinkage included. Once the model is in the computer,

it can be scaled to ANY size.

Let's take an example....

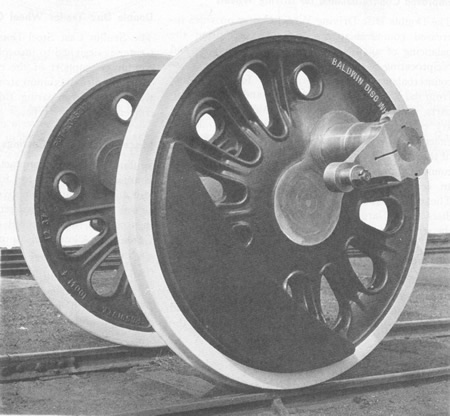

Here is a photograph of a Baldwin Disk driving wheel for a steam locomotive

taken from the 1938 Locomotive Cyclopedia.

From this, and from some additional resources, we produce a model in the computer.

Finally, we export the model to the SolidScape modeler and we produce this beautiful wax model.

From the wax model, we send it to our caster and have this excellent master made. Production parts are soon to follow...

The process we use here is identical to that used in the jewelry industry. However, we need to go a step further. Because it is virtually impossible to polish model train, ship and airplane parts (take the wheel we just made above!), our models are produced with extremely fine surface roughness. One of the anomalies from any stereolithography process is the stair-step features seen primarily on curved surfaces. These are due to the way in which the model is broken-down and built-up on any stereolithography process. The thicker the layers used to build the model, which also results in a quicker build time, the coarser the surface roughness.

In the jewelry industry, models are usually produced with visible stair-step features and then polished away. But polishing is not on option for the models being produced for our customers, often times they are cut from the sprue and then directly soldered on a larger assembly. Therefore, we produce our models using the finest possible layering thickness: 0.0005". That is five ten-thousandths of and inch, or 13 micrometers. The stairstepping is so small, you'd need a magnifier to see it. And after the model has been cast, rubber molded, and cast again (for production parts), the stair-stepping has virtually disappeared.